Where is Asbestos Hiding in Interior Products?

After reporting on the Environmental Protection Agency’s Significant New Use Rule (SNUR) of asbestos on Aug. 8, 2018, many questions that we received asked how asbestos are still being used. Due to misunderstandings surrounding bans made on asbestos in the 1970s, it is generally thought that the crystalline material has faded out of use in recent decades.

However, those in the building industries should be aware of the continued use of asbestos to create chlorine gas, which in turn is needed to create PVC—a main component in vinyl that makes up flooring, wallcoverings, upholstery, and more.

Article Navigation

The Chemistry | The HBN Report | In Chlorine Production | Building Products

In the Americas | Asbestos Mining | In Europe & Africa | For Designers

The Chemistry of Chlorine Gas and Asbestos

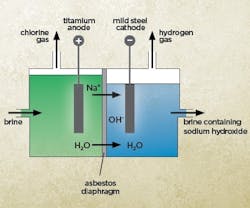

Chlorine gas—different from chlorine liquid—is created through electrolysis of sodium chloride solutions.

In this process, an electric current passes through the liquid, sodium chloride (rock salt found in liquids such as salt water). Through electrolysis, hydrogen and sodium ions form in the anode compartment (the positively charged conductor).

The electrolyte level is higher in the anode compartment than the cathode (negatively charged conductor) compartment so that these hydrogen and sodium ions are pulled towards the cathode. Ions want to stay neutral, so positive ions will be attracted to negative charges, and vice versa.

Without a barrier between the two compartments, the ions would be able to flow back and forth between the anode and cathode to achieve neutrality, and the entire solution would form sodium hypochlorite.

To keep the two compartments separate by using a percolating diaphragm cell, asbestos is used to separate the chlorine and hydrogen gas spaces. The OH- ions are prevented from flowing back to the anode compartment to achieve neutrality by the asbestos diaphragm and the velocity of liquid flow against them.

During this process, chlorine forms around the positive anode during the separation of the sodium and hydrogen. These chlorine molecules rise out of the anode chamber, while hydrogen gas and sodium hydroxide are released from the cathode chamber.

Healthy Building Network’s Chlorine and Building Materials Report

In July 2018 when the EPA’s ruling was made, the Healthy Building Network (HBN)—a nonprofit research body that has worked to increase transparency in the building industry, reduce human exposures to hazardous chemicals, and create market incentives for healthier innovations in manufacturing—released their first of two research reports on the use of chlorine gas in the buildings industry.

The study was supported by both PVC-manufacturing and non-PVC-manufacturing companies within the design industry, including:

Their sponsorship allowed for a not only broader research on the topic of transparency of building materials, but began the conversation in the architecture and design community surrounding the topic.

The network first presented its study on the use of asbestos in the PVC-production supply chain as part of a dialogue with PVC manufacturers during Greenbuild. Bill Walsh, president, HBN, said, “What was surprising was that many end-product manufacturers were really surprised that they may have had asbestos, or possibly mercury (the other process used to make chlorine) in their supply chain. They approached us to help them determine whether they did.”

Although, the non-profit work with manufacturer sponsors, HBN determined that it could map the supply chains of chlorine to help those companies begin to gain better insight. That research became Chlorine and Building Materials: A Global Inventory of Production Technologies, Markets, and Pollution; Phase 1: Africa, The Americas, and Europe.

The first of two reports—the second will focus on plants within Asia—“covers the 86 largest chlor-alkali plants and 56 largest PVC plants in the Western Hemisphere, Africa, and Europe. It analyzes chlorine markets with an emphasis on the PVC supply chain, chlorine production technologies, and pollution associated with the production of chlorine and chlorine-based products.”

“This Healthy Building Network report establishes basic facts concerning chlorine production. Who is producing chlorine? Where? How much? And with which technologies? What plans exist to stop using mercury or asbestos to make chlorine? What products use the chlorine made in each plant? What harm has been caused by each chemical plant’s operation?”

The report was researched from August 2017 to May 2018.

When speaking with Walsh, he first made it clear “that the asbestos does not carry through your wallcovering or floor covering or upholstery.” While there are concerns with older vinyl and PVC, current technologies do not leave the consumer at risk of being exposed to asbestos, nor has it been found in recycled products that HBN has tested.

The issue of asbestos and mercury use primarily affects the manufacturing process. Although asbestos and mercury aren’t found in finished vinyl products, manufacturers find it concerning that their products have the potential for creating health issues in those in the production chain.

Again, asbestos contact doesn’t occur in finished products.

The Use of Asbestos in Chlorine Production

As the HBN’s 150+ page Chlorine and Building Materials report states: “Chlorine production uses and releases mercury, asbestos, and other highly toxic pollutants. Chlorine gas is created in an energy-intensive industrial process that splits brine (salty or brackish water from oceans or underground sources) into equal parts chlorine gas and caustic soda. Four technologies are currently used in this process. The two oldest types of technology rely upon asbestos or mercury, which are then released into the environment. Newer technologies use a Teflon-like coating of per- and poly-fluroralkyl substances (PFAS).”

Health and environmental impacts of per- and poly-fluoroalkyl substances are currently unknown as “more research is needed to understand the environmental health impacts of these [production] plants.”

Hospitality News ► The Graduate Hotels Bring Nostalgic Vibes

The chlorine gas created is unlike liquid chlorine, found in swimming pools and the like, which accounts for less than 10 percent of chlorine use. In comparison, chlorine gas has been used as chemical weapons.

Article Navigation

The Chemistry | The HBN Report | In Chlorine Production | Building Products

In the Americas | Asbestos Mining | In Europe & Africa | For Designers

Where is Chlorine Used in Building Products?

Chlorine gas makes up about 50-60 percent by weight of the content of vinyl.

Most of the asbestos used in the United States comes from this process, explained Walsh. “It’s virtually all—and we say virtually because we have not identified any other source, but perhaps there is some sort of corner case where asbestos is still used in the United States—but our studies show that all of the asbestos imported into the United States is imported by chlorine manufacturers. Now, not all chlorine is created using asbestos. This is kind of an antiquated technology.”

Most of the chlorine gas produced in the world makes four plastics:

- PVC

- epoxies

- polycarbonate,

- polyurethane.

Chlorine Production in the Americas

While it’s generally believed that asbestos is no longer found in America, the 1970s ban on asbestos did not include using the crystalline material to create chlorine gas.

According to the HBN, asbestos is used in chlorine creation in 11 plants in the United States, including 7 of the 12 largest plants in the Americas. These 7 plants are located on the Gulf Coast.

The plants which use asbestos technology supply 7 of 16 PVC resin plants in the United States.

[Harvesting Natural Light for Interiors]

Asbestos is used in 45 percent of the chlorine production in the United States. (Only two plants in the United States—in West Virginia and Ohio—use mercury cells. The Ashta Chemical plant in Ohio plans to convert away from mercury in 2019.)

Where the Asbestos is Mined

Another fact that may be surprising is that the 1970s ban on asbestos didn’t include the mining of the material either. Mining didn’t cease in the United States until 2002, and it finally ended in Canada in 2011.

Therefore, American plants have relied on importing asbestos for the last decade and a half.

Until recently, HBN found that U.S. manufacturers were dependent on asbestos imports from Brazil. Between 2014 and 2017, plants run by three corporations—Olin, Occidental, and Westlake—imported an average of 480 tons of asbestos each year. These three companies consumed all of the asbestos imported in 2017.

But imports from Brazil will soon come to an end. In 2017, Brazil announced a national asbestos ban. While mining is still occurring in Brazil, operations are expected to cease over the next few years as the country enacts its bans.

When this occurs, all asbestos imports will come from Russia, the United States’ last supplier.

Asbestos Use in Europe and Africa

Despite asbestos being banned in 60 countries, there is one plant in Germany and two in Russia which still use asbestos, having been in production prior to the ban. The German plant is the largest complex in all of Europe, producing up to 1.03 million tons of chlorine per year via asbestos. They currently have enough asbestos to continue operations through 2025.

Africa is the only continent (besides Antarctica) that doesn’t use asbestos or mercury in chlorine production.

What Does This Mean for Designers?

While asbestos contact doesn’t occur once the PVC is made and isn’t found in products such as vinyl which utilizes PVC, for an industry that is becoming increasingly concerned about transparency, its important to note its use and the risks of contact for people working in mining or production and living in the surrounding community. A city located close to a Russian mine recently disclosed that a film of asbestos had settled upon the town, including covering fruits and vegetables in grocery stores.

There are many positive attributes of vinyl. Currently, it’s the best option when creating long-lasting interiors that experience wear and tear. Vinyl products can minimize the need for replacement, which in turn minimizes the amount of products that go into landfills.

The importance is in the industry being aware of asbestos use and the ways in which vinyl products impact health and ecology.

In response to the HBN’s report, Walsh says companies using PVC have become more aware and have already begun planning for next steps.

“There has been some talk by some of [the companies sponsoring the report] to say ‘Maybe we can even make a commitment to not use virgin PVC.’ For example, Interface and Tarkett both have very robust programs for recycling PVC in an effort to lower the virgin content in their products. I believe Interface has a goal … to reach 100 percent recycled PVC because they’re only using it in the backing of their product.”

The production process is in the hands of manufacturers, but interior designers can:

- Make themselves aware of the issue and ask for transparency from their manufacturers.

- Calculate their vinyl use to reduce excess purchasing that will go unused.

- Use products that utilize recycled, non-virgin PVC.

- Research recycling programs to create an end-of-life plan, as well as safely recycle existing vinyl if it’s being replaced.

Specify vinyl and other PVC products in strategic ways, such as using vinyl wallcoverings used in public spaces of a hotel but specifying paper or natural materials for the wallcoverings in individual rooms.

Article Navigation

The Chemistry | The HBN Report | In Chlorine Production | Building Products

In the Americas | Asbestos Mining | In Europe & Africa | For Designers

► Daily Design News | Joanna Gaines Enters Commercial Design | The Wing’s Is Fit for a Queen

About the Author

Kadie Yale

Former Editor-in-Chief

Kadie Yale holds a BA in Industrial Design from San Francisco State University and a MA in Decorative Art History and Theory from Parsons the New School. In her role as editor-in-chief from 2015-2018, she led the interiors+sources team in creating relevant content that touches on sustainability, universal design, science, and the role of design in society.