When it comes to developing more affective carbon strategies, we have tremendous buying power as an industry. Rethinking the embodied carbon of building materials is one of the greatest opportunities we have as architects and interior designers to reduce the environmental impact of our work. While this can seem intimidating, today’s tools and technologies make it easy to start tracking and implementing a lower carbon footprint on any project.

Case in point: The Embodied Carbon in Construction Calculator (EC3) is a free, easy to use tool that empowers designers to take control of their project’s embodied carbon. Focused on the upfront supply chain emissions of building materials, the tool draws from a growing database of third-party verified Environmental Product Declarations (EPDs) that can combine with project-specific material quantities from construction estimates and BIM models, enabling the specification and procurement of low-carbon options.

EC3 was incubated at the Carbon Leadership Forum with input from nearly 50 industry partners, including ZGF Architects. Its powerful impact on the AEC industry has driven demand for low-carbon materials and incentivized many manufacturers and suppliers to invest in disclosure, transparency and innovations that reduce the carbon footprint of their products.

From core and shell design to interior fit outs, ZGF utilizes EC3 to accomplish several things throughout a project’s lifecycle. Interiors can have a greatly underestimated impact on carbon, especially spaces that receive frequent retrofits. Early in design development, we can identify industry baselines for a wide range of building materials and compare them with lower-carbon options. During procurement, we can integrate those low-carbon options into our specifications. Down the road, the resulting EC3 model makes as-built embodied carbon documentation easier and supports green building certifications, including LEED pilot credit for reducing embodied carbon.

1. Unlock Innovative Solutions

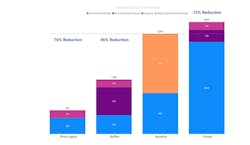

ZGF was among the first EC3 pilot users in 2019, starting with a large campus modernization project for a global technology client, which is on track to achieve ILFI Net Zero Carbon and LEED Platinum certifications. The project targeted more than 50% reduction in embodied carbon from low-carbon concrete mixes and nearly 25% reduction in the overall project including the building envelope. Our team used Tally and EC3 for carbon modeling and led a low-carbon concrete integrative process with the structural engineer, general contractor and concrete supplier.

The tool was a gamechanger for collaborative carbon accounting. What started out with a structural and enclosure focus grew to interiors, which accounted for 17% of the project’s total embodied carbon. EC3 allowed us to break that down by material category and pinpoint which ones were driving the greatest impact. Gypsum wallboard seemed like low hanging fruit; however, specifying a low-carbon, ultralightweight gypsum impacted acoustics. Our engineers creatively solved for this by increasing the spacing between wall studs from 16 inches to 24 inches, yielding even greater carbon savings due to the reduction in stud material. Only by evaluating interior partitions holistically as a system did we realize this solution, and it drove down the total embodied carbon by 1.5% with no change to budget or schedule.

We also looked deeper at the embodied carbon of commercial carpet tiles. Initially the design included carpet patterns from several different manufacturers, but using EC3 we discovered we could reduce the overall embodied carbon by 1.78% from the baseline simply by switching to one manufacturer with the lowest carbon footprint.

2. Compare and Contrast Low Carbon Materials

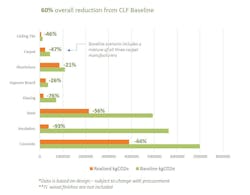

For another client, ZGF was tasked with reducing the embodied carbon of interior materials without impacting the budget. We utilized EC3 to generate a baseline model representing their typical practice and a duplicate model with low-carbon materials to show the hotspots, or opportunities for savings.

For instance, we compared the following ceiling options in the break room and their impacts on acoustics as well as embodied carbon: lay-in mineral fiber ceiling tile (baseline); a dropped fiberglass cloud solution; suspended PET felt acoustic baffles; direct-apply PET felt acoustic panels. The direct-apply PET felt panels offered the lowest carbon footprint while maintaining acoustic requirements due to its lack of aluminum suspension system and low embodied carbon of high recycled content PET. It also allowed the mass timber structure to be more exposed and celebrated. It was still the lowest-carbon solution even with the extra gypsum board material needed to finish the walls up to structure now that the baseline lay-in ceiling tile was removed. This resulted in a 76% carbon reduction from the baseline model. EC3 made it easy to model these scenarios with the material quantities and embodied carbon, and the client appreciated seeing the realities of each option.

3. Embed Carbon Limits in Spec Generation

More broadly, EC3 unlocks opportunities to set our own embodied carbon baselines and embed them in our specifications as ZGF standards. From healthcare to higher education projects, our designers are deep-diving into commonly used materials like resilient flooring, carpet, and ceiling systems to set reasonable limits, or maximum global warming potential (GWP), for the Product Stage (A1-A3) in our specifications as demonstrated by the product’s EPD.

EC3 is a great starting point for product research because it cuts the time-intensive task of converting different units of measurement, such as metric to imperial. The tool normalizes these numbers, making them easy to compare and vet further. It levels the playing field so all designers can make more informed decisions about low-carbon solutions.

But it doesn’t stop with designers; we’re building EC3 into our contracts with consultants, so they have access to our structural, shell and core, and interior models. It adds to our digital toolbelt another way to collaborate, innovate and hold each other accountable for meeting embodied carbon goals.

We’re consistently seeing interiors account for 10% to 20% of total embodied carbon emissions across our projects. There are so many great resources now available for designers to lower the carbon footprint of their projects and the EC3 is at the top of our list.