What is it made of? Where did it come from? How was it made? How is it maintained? What happens to it at the end of its useful life? How does it affect the health of building occupants?

These are the questions we’ve been asking for decades trying to define green products, and in the process, we have ended up with a plethora—some might more accurately say a chaotic conglomeration—of definitions, lists, standards, certifications and labels that do little more than confuse the heck out of us. According to estimates, there are more than 300 material evaluations, often contradictory and frequently redundant. Each has its advocates, of whom designers and specifiers need to ask the most important question of all: how do I know you are telling me the truth?

Trying to sort it out takes time and a level of knowledge beyond our expertise. The issues are equally difficult for manufacturers who must weigh many different issues when making their choice of what ecolabels to get for their products.

What we really need is a transparent, understandable standard format for defining and reporting the product content of building materials and furnishings. And yes, the impetus is on the manufacturer to get the information to us versus the current system where it is the designer/specifier’s responsibility to sort through, understand and substantiate the veracity of environmental claims.

Luckily there are two formats, one established and one emerging, that will help both manufacturers and their customers. Both are voluntary and are grounded in transparency—the big, new (and overdue) movement in building design and construction.

EPD, meet HPD

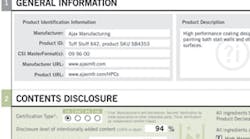

First up is the Environmental Product Declaration (EPD). Born in Sweden and used primarily in Europe (though it is gaining traction in the U.S.), its purpose is to clarify the environmental impacts of the products and materials we use in our buildings, just as nutrition labels let you know what’s in your food. EPDs begin with a detailed Life Cycle Assessment (LCA) from raw material extraction to end-of-life based on internationally accepted methods (ISO 14025).

Having an EPD does not guarantee a product’s environmental soundness, only that the manufacturer has put the product through the process. However, since all products are classified into categories with established impact Product Category Rules (PCRs), it makes comparisons between products possible, and that’s a good thing.

EPDs are comprehensive, exposing warts and all, but don’t necessarily include a manufacturer’s complete product line. And, though simpler than a LCA, they are intimidating. However, for all their complexity, EPDs don’t tell the whole story. They specifically neglect health-related concerns associated with product content, a gap that has led to the development of a second resource, the Health Product Declaration (HPD).

Begun in July 2011 by the Materials Research Collaborative, a joint initiative of the Healthy Building Network and BuildingGreen, the effort is being directed by the Open Standard Working Group, a voluntary association of expert participants from the community of building designers, specifiers, owners and users.

This is huge! An open standard is one that is held in the public domain, with its use intended to be freely licensed to all. It is intended to be developed, maintained and evolved in an open process, encouraging widespread industry participation and adoption.

What this means, according to Bill Walsh, executive director of the Healthy Building Network, is a level of rigor “designed to maximize disclosure and accuracy of building product data, and ensure that it is reported in a fair and consistent manner wherever it appears. The program is also designed to test the limits of what manufacturers know about the contents of their building products, and what they are willing to disclose to their customers.” No more fudging, skewing or spinning the data, and no more greenwashing—at least not as easily.

Thirty leading building product manufacturers encompassing everything from structural components to office systems have signed onto the HPD pilot program. (Enrollment is now closed.) The process, as outlined by Walsh, requires each participant “to complete an HPD for as many as three products, and to provide the HPD Working Group with feedback. HPD Working Group members are providing the manufacturers with a reference guide, webinars and technical collaboration to help refine the HPD to be reliable and actionable for end users, and reasonable and fair to all manufacturers. The companies will also receive support from the Pharos Project, a project of the Healthy Building Network, which will provide access to its extensive Chemical and Material Library through its web-based Pharos system. The Working Group will evaluate and synthesize the feedback from the participating companies, and revise the draft HPD into a final version that will be officially ratified and made available to the public later this year.”

The story behind the formation of the HPD pilot program is both inspirational and yet somehow typical of the green building movement, where innovation often occurs because of the passions and actions of one person or company. In this case it was the Swedish manufacturer ASSA ABLOY, the world’s largest provider of door security solutions. While working on developing Product Category Rules and conducting LCAs for the EPDs required by many European countries, the staff of ASSA ABLOY had an “ah-ha” moment. EPDs miss what is arguably the most important aspect of environmental transparency: the human health impacts.

According to Aaron Smith, director of sustainable building solutions at ASSA ABLOY, the company was already engaged with Healthy Building Network’s Pharos system and learned that a customer-led working group was developing the HPD. After realizing that the project fell in line with its dual corporate goals of transparency and environmental transformation in its product division, the company volunteered to use some of its products to troubleshoot and improve the draft format. Three more firms signed on—InterfaceFLOR, Scranton Products and YOLO Colorhouse—in time for the public debut of the draft HPD at Greenbuild 2011, and the pilot program was underway.

Smith admits that filling out the HPD forms can be daunting—akin to herding informational cats—and that some companies may have a problem with divulging proprietary data. However, it is important to understand that the HPD is a format for gathering information and health effects that will be used in many other reporting documents.

“ASSA ABLOY is excited about HPDs,” says Smith. “It moves our industry forward and gets us ahead of evolving codes and standards, plus it’s the right thing to do.”

Product transparency is emerging as an essential component of green design. If adopted as currently written, LEED 2012 will offer points for products with an EPD. GreenSpec has added product transparency as a search attribute. InterfaceFLOR has committed to providing EPDs for all its flooring products by 2012, and some large companies—Google, for instance—insist upon it for all material decisions in their facilities.

It is incumbent for our entire industry to step up. Designers, demand transparency. Manufacturers, provide transparency. Really, without it, how do we know you’re telling us the truth?

You can learn more about EPDs at www.environmentalproductdeclarations.com; information about HPDs is available at www.hpdworkinggroup.org.

Penny Bonda, FASID, LEED AP ID+C works in the fields of environmental consulting and communications, and is a prominent writer and lecturer. She is the founding chair and a primary author of the LEED Commercial Interiors rating system. Her published works include Sustainability Matters, written with the General Services Administration, and Sustainable Commercial Interiors (Wiley). She is a founding partner of Ecoimpact Consulting, an collaborative offering sustainable strategies for better business.